Sometimes it can be very handy to manually control your fuel pump of your 5 liter Mustang. Perhaps you want to set fuel pressure, or pump all the fuel out of your tank and into a gas can. Whatever your reason for wanting to run the pump, just turning the key on won't cut it. The fuel pump only runs for one second unless the crankshaft is turning. Today, I'm going to show you how to bypass that and run the pump non-stop.

The computer is in charge of running the fuel pump. However, the computer doesn't directly supply power to the pump. Instead, it turns on a fuel pump relay, which in turn sends power to the pump. The fuel pump relay has two sides to it; the control side, and the load side.

The load side is the high amperage side, and consists of two wires. One is power going from a fusible link on the starter relay to the fuel pump relay, and the other is power going from the fuel pump relay, through the inertia switch, and to the fuel pump. In a Fox Body, relay terminal 87 is the power input, and terminal 30 is the power output. In an SN95, the fuel pump fuse sends power to pin 11 on the Constant Control Relay Module, and the CCRM sends power out to the fuel pump from pin 5.

The control side is the low amperage side, and also consists of two wires, a power and a ground. When power and ground are applied to the control side of the relay, that turns the relay on and connects the two load side wires together, completing the power circuit to the fuel pump. In a Fox Body, a fusible link runs through the EEC Power Relay (when the key is on), and powers up the fuel pump relay's control side power terminal, which is relay pin 86. The control side ground comes from the computer's pin 22 and runs to terminal 85 on the fuel pump relay.

To simplify this, let's just say that when you turn the key on, the EEC Power Relay sends power to the Fuel Pump Relay all the time, so that when the computer sends a ground signal to the relay, the relay turns on.

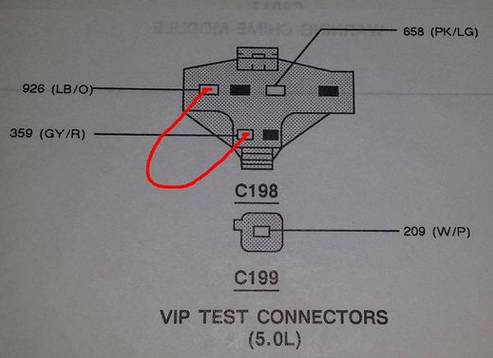

The wire that runs from pin 22 on the computer to terminal 85 on the fuel pump relay is the ground/control wire. On SN95 Mustangs, this wire runs from computer pin 22 to pin 18 on the CCRM. On all 87-95 5.0L Mustangs, this wire also runs to The VIP Test Connector under the hood, also known as the EEC-IV diagnostic connector or Data Link Connector.

In the VIP Test Connector diagram shown above, you will see circuit 926 (Light Blue/Orange wire). This is the fuel pump relay control wire that we are interested in. If you jumper this terminal to ground while the key is on, the fuel pump will run non-stop.

Conveniently, the terminal right below circuit 926 is circuit 359 (gray/red wire), which is the computer's sensor ground circuit. So if you build a jumper wire out of 16 gauge wire that is about 3 or 4 inches long, and has a 1/4" male spade connector crimped onto each end of the wire, you can insert this jumper wire into terminals 926 and 359, and this will turn on the fuel pump relay and run the pump.

If you want to pump the entire tank of fuel out of your Mustang, you can remove the schrader valve from the fuel rail, connect a Ford fuel pressure test hose to the fuel pressure test fitting, and dump the hose into a gas can. Then jumper terminal 926 to terminal 359 and watch the fuel flow into the can.

Another convenient use for terminal 926 is to test if the computer is commanding the pump to run. The computer will turn the fuel pump relay on for one second every time you turn the key on, but it will only continue to leave the relay on if the crankshaft is turning and a PIP signal is being generated by the distributor.

If we want to check for computer control of the fuel pump relay, we need to use an LED test light. A regular incandescent test light is not a good idea here, because the amount of current required to turn on an incandescent light bulb may be more than the computer's driver was designed for. In other words, you could damage the computer here if you use a regular incandescent test light. So use only an LED test light for this test!

All you have to do is hook an LED test light up to the battery positive terminal or the hot side of the starter relay. Then gently touch the tip of the LED test light to terminal 926 on the VIP test connector. When you turn the key on, you should see the test light bulb light up for one second. When you are cranking the engine over, you should see the test light bulb light up as long as you are cranking the engine over.

This test is quite useful. Other than the one second prime of the fuel pump, the only time the LED light should light up is when the computer is receiving a PIP signal from the distributor module. So if you suspect the distributor's pick-up coil (PIP sensor) or ignition module is bad, this test will tell you if the computer is receiving the PIP signal from the module or not.